Mining

Our product range for use in mining

Our mining solutions

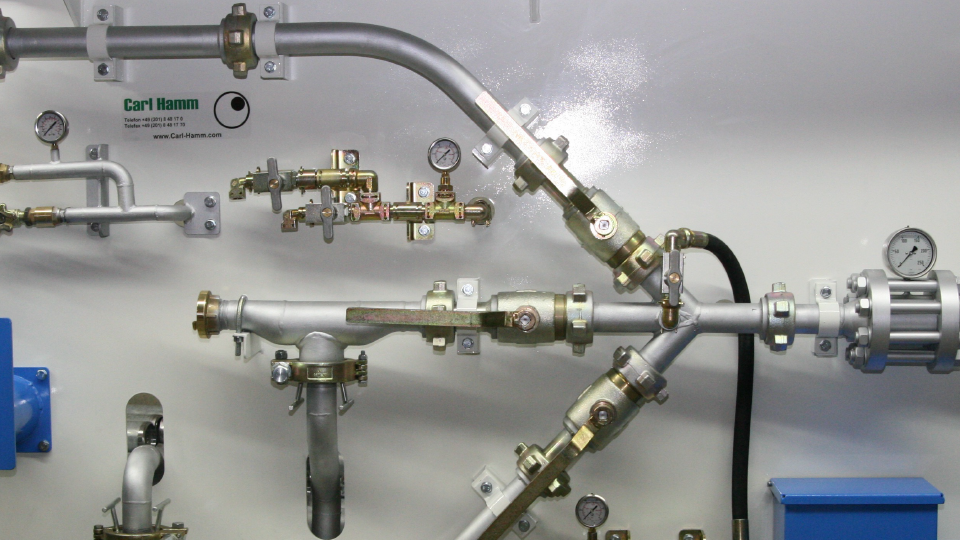

Pipes and connection systems are vital in mining. The quality of the shaft pipes, flange connections and all other components must be correspondingly high. We develop and manufacture modern pipelines and connection technology elements for use above and below ground that reliably withstand the high loads in mining.

Unsere Lösungen für den Bergbau

Im Bergbau sind Rohre und Verbindungssysteme lebenswichtig. Entsprechend hoch muss die Qualität der Schachtrohre, Flanschverbindungen und aller weiteren Bauteile sein. Wir entwickeln und fertigen moderne Rohrleitungen und Elemente der Verbindungstechnik für den Einsatz über und unter Tage, die den hohen Belastungen im Bergbau zuverlässig standhalten.

Experience

90+ years of experience supplying open-pit mines as well as underground mining operations.

Reliability

20+ years as a system supplier for Deutsche Steinkohle (RAG), providing high- and low-pressure piping systems.

Diversity

A wide range of connection solutions for the open-pit mines of RWE / Rheinbraun (Garzweiler / Hambach).

Reach

Supplying mines on multiple continents with products and services.

Complete Solutions

Extensive experience in delivering turnkey dewatering solutions for active and abandoned mining operations.

Applications of Our Piping Systems

Horizontal Pipelines

We are a system supplier for Deutsche Steinkohle, providing all underground low- and high-pressure steel pipelines.

Feed Lines

For feed lines in mining, we manufacture high-quality and durable flanged pipes and high-pressure coupling pipelines.

Transport Lines

For underground transport lines, we supply water and cooling pipelines.

Vertical Pipelines

Suspended or standing pipelines, primarily using the ZSM connection system, alternatively with flanged connections.

Well Pipes

Deep well pipes with the ZSM connection system for open-pit dewatering and general use in deep well systems.

Shaft Pipes

ZSM and flanged connections used for supply lines and shaft dewatering.

Complete Solutions

From conceptual planning and manufacturing to on-time delivery.

Prefabrication of individual components ready for assembly is standard practice in our facility.

In addition to producing standard and custom components according to customer specifications, our expertise also lies in the development of complete solutions. This means we support our industrial and plant engineering clients from the planning phase through to production. Based on individual requirements and needs, our technicians develop the perfectly tailored pipes and piping systems, which are then manufactured with the highest precision using our extensive machinery.

Non-destructive testing is also carried out in-house by specially trained personnel. If external inspections are required, we collaborate with various institutes such as TÜV or DNV GL.

On-site inspection

Concept development

Preliminary design

Detailed engineering

Centrifugal pumps

Submersible pumps

Piston pumps

Complete system installation

Installation supervision

Employee training

Component selection

Gate valves

Ball valves

Check valves

Air release and intake valves

Safety valves

Frequency converters

Power converters

Control cabinets

Remote monitoring systems

Control rooms

Power cables

Cable clamps

Pipe trace heating systems

Cable laying systems

Conveyed Materials

- Water

- Slurry

- Hydraulic fluids

- Gasoline / Diesel

- Air

- Compressed air

- Gas

- Concrete / Cement

- Explosives

Verbindungsarten

ZSM

The tensile-resistant socket joint—ZSM for short—is a positive-locking and detachable pipe connection. It is used in shaft pipelines for underground mining and deep well construction.

Our patented socket system offers an attractive alternative to other common connection systems thanks to its quick and easy assembly/disassembly, minimized space requirements, and cost-effectiveness.

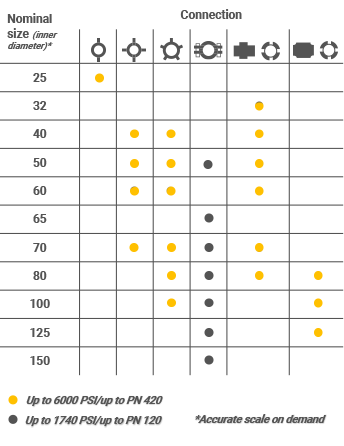

High-pressure couplings

Hochdruck-

verschraubungen

Transporting hydraulic fluids over long distances without significant pressure loss is one of the major challenges in modern plant engineering. Carl Hamm relies on centralized pump stations in this sector, ensuring efficient and reliable supply of hydraulic fluids to shield supports.

The system is already successfully in use at various facilities worldwide. It demonstrates its particular strengths, for example, in mining, water supply, and spraying systems. Other application areas outside these sectors are also possible, where centralized pump stations are used for transporting different materials.

Manufacturing takes place at our plant, supplemented by the procurement of all additional components:

- Pipes

- Fittings

- Distributors

- Special parts

- Valves

- Hoses

Flanges

Flanges according to EN or ASTM standards, from 17.2 mm to 2,000 mm, covering all pressure ratings, as well as custom flanges based on customer specifications (e.g., WN 110).

In our own mechanical workshop, we can machine flanges to your specific requirements, such as raised and recessed faces, cable cutouts, s-dimension machining, and much more. In addition to standard flanges, we also manufacture custom flanges according to drawings or samples. Naturally, we can also apply any desired corrosion protection to the flanges.

Quick couplings

With SK Quick Coupling Technology, pipes of the same type can be joined quickly and easily with just a few simple steps. This connection can also be separated just as quickly. In some cases, this connection method is referred to as “Lanninger pipes,” named after the inventor Karl Ludwig Lanninger. Typically, the pipes are made of hot-dip galvanized steel, are usually 6 meters long, and are produced with internal diameters of up to 300 mm.