ZSM

Inseparable Connections. Discover the Strength of ZSM Solutions

Unzertrennliche Verbindungen

Die zugfeste Steckmuffen Verbindung

Die zugfeste Steckmuffenverbindung – kurz ZSM – gehört zu den längskraftschlüssigen und lösbaren Rohrverbindungen. Sie wird in Schachtleitungen im Untertagebergbau und im Tiefbrunnenbau eingesetzt.

Unser patentgeschütztes Steckmuffensystem stellt aufgrund der schnellen und einfachen Montage/Demontage, des minimierten Platzbedarfs sowie des günstigen Preises eine interessante Alternative zu anderen gängigen Verbindungssystemen dar.

The Tensile-Resistant Socket Joint

The ZSM (short for Zugfeste Steckmuffenverbindung, German for “tensile-resistant socket joint”) is a positive-locking and detachable pipe connection. It is used in shaft pipelines for underground mining and deep well construction.

Our patented socket system is an attractive alternative to conventional connection systems due to its quick and easy assembly/disassembly, minimal space requirements, and cost-effectiveness.

The Success Story of ZSM

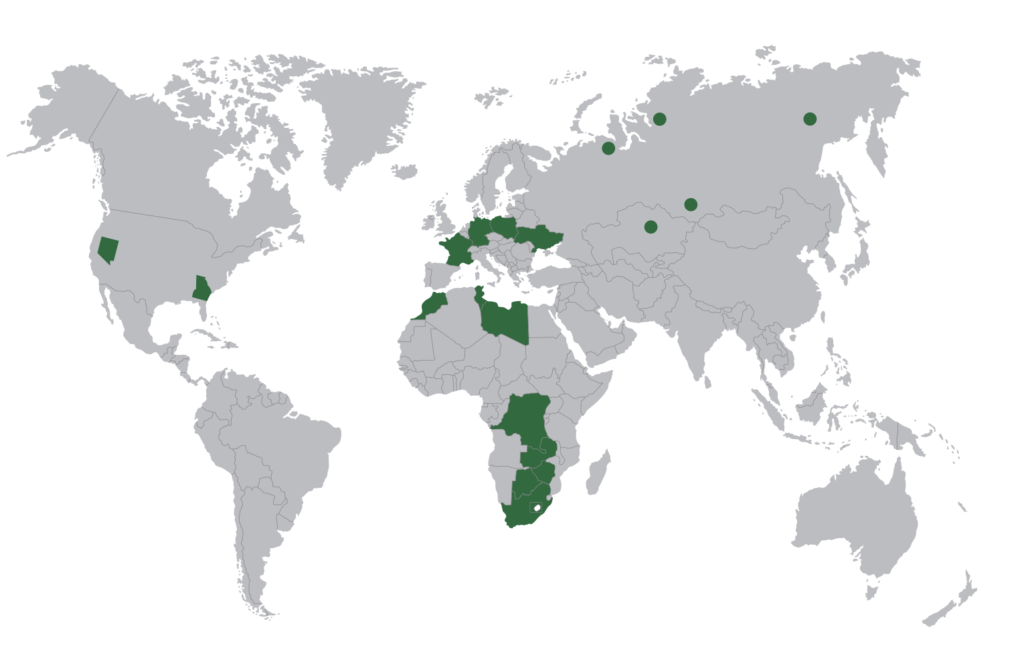

The ZSM connection (Zugfeste Steckmuffenverbindung) was introduced in 1992 as a simple, fast, and leak-tight joint, initially used in well construction. During the 1990s, its potential was recognized, and it was further developed in cooperation with Rheinbraun (now RWE Power). This innovation revolutionized Rheinbraun’s well operations, leading to the exclusive use of ZSM piping in all their wells.

In 2003, the first riser pipe in the German hard coal mining industry was installed with ZSM technology at the Heinrich Shaft in Essen. Since then, the ZSM connection has been continuously refined and successfully applied in a variety of international installations.

ZSM

Reliable and Detachable Pipe Connections for Various Applications

Safe solutions for a wide range of piping systems.

- Pressure Pipes

For pipelines transporting liquids under pressure, this system provides tight and secure connections—even under high-pressure conditions. - Casing Pipes

Used for lining boreholes in well drilling; they offer strong and stable support to maintain structural integrity. - Filter Pipes

Designed for filter systems, they provide leak-tight connections to ensure the effectiveness of the filtration process. - Non-Pressurized Pipes

For pipes that do not carry pressurized liquids, this system offers reliable connections that are easy to assemble and disassemble.

Fields of Application

ZSM connections are versatile and used across numerous industries and applications.

- Underground Mining

For pipelines transporting pressurized liquids, ZSM provides leak-tight and secure connections, even under high-pressure conditions. - Open-Pit Mining

Used for lining boreholes during well drilling, offering robust and stable support to maintain structural integrity. - Deep Wells

Ideal for filter systems, ensuring tight connections that maintain filtration efficiency. Also suitable for non-pressurized pipelines, offering reliable, easy-to-assemble and disassemble joints. - Medium and Deep Geothermal Applications

- HDD – Casing Pipes

Why choose ZSM?

Fast

Quick installation and removal

Simple

No special tools or personnel required

Compact

Minimal space requirement

Durable

High tensile and pressure resistance

The Fastest Solution

Compared to other methods, this is the fastest.

How fast? Watch this video to find out.

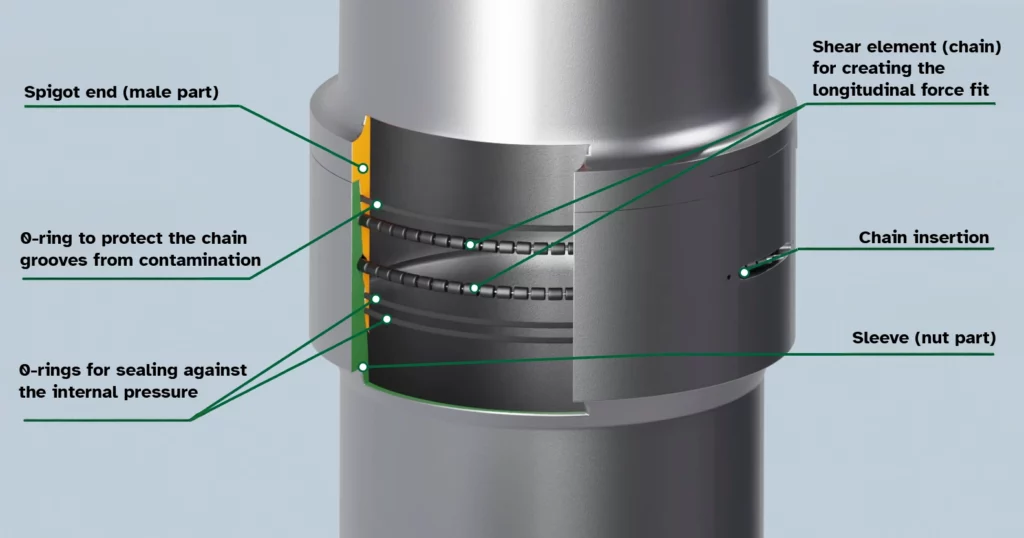

How Does It Work?

Quick on-site assembly without welding or bolting.

Easy insertion of two chains.

Results

Technical Data

Pressure Pipes

DN 50 – DN 800

Up to PN 400 (depending on size)

Lengths up to 16 m

Axial loads up to 1,800 tons (breaking load)

Material groups:

Steel (alloyed/unalloyed)

Stainless steel

Duplex / Super Duplex

Various corrosion protection options

Construction Pipes

Used for securing electrical cables

Non-Pressurized Pipes

Used as downpipes

Used for fastening electrical cables

Used as outer casing in pipe-in-pipe systems

Casing Pipes

Up to DN 1400

Lengths up to 12 m

Designed according to customer specifications

Our Services

Engeneering

Our engineering services cover a wide range of activities. We start with budget planning based on the information you provide, followed by a preliminary design of the piping system. We offer detailed piping layouts and structural calculations to ensure integrity. Both overview and detailed part drawings are created, and destructive tensile tests are performed.

Manufacturing

Our process includes the production of the piping system, non-destructive weld inspections, and the application of internal and/or external coatings. We also provide comprehensive documentation for external testing procedures.

Turnkey Solution

Our Turnkey Solution is the full package: we manage complete projects from engineering, production, installation, inspection, and commissioning to final handover—ready for operation.

- Material procurement

- Worldwide shipping

- Supervision of assembly or

- Complete assembly of the pipeline

- Electrical cables

- Cable holder

- Controller

- Frequency converter

- Visualized control

- Assembly

- Flow diagram (water)

- Programming control unit

- Commissioning

- Training

- Material procurement

- Worldwide shipping

- Supervision of assembly or

- Complete assembly of the pipeline

- Turnkey Solution

- Project management

- Installation

- Commissioning

- Technical monitoring

- Pumps

- Frequency converters

- Electrical control

- Electrical cables

- Fittings

Support

Our support services include pipeline production, non-destructive weld testing, and the application of internal and/or external coatings. In addition, we provide documentation and support for external testing to ensure compliance.